As Tyson Food’s Richard Bond led an initiative to cut costs and improve earnings, he no doubt eyed the costly but necessary food safety and animal health division.

The company announced yesterday that it will collaborate with Luminex to create faster, more accurate and cost-effective food safety and animal health tests.

Tyson’s Food Safety Network comprises 17 laboratories spread across the country. This includes a 25,000-square-foot food testing and research laboratory in Springdale, Arkansas.

The first initiative is the development of an avian flock health monitoring panel. Future research and development projects will be focused on food safety and quality, and additional animal health diagnostic panels. Luminex will leverage its xMAP technology to develop tests that screen for pathogens and other microbes more efficiently and accurately.

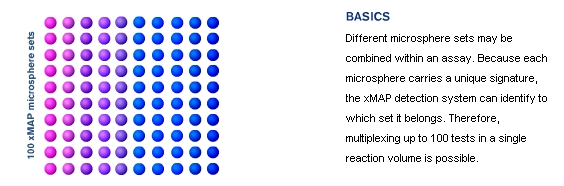

xMAP enables multiple tests to be run simultaneously on one sample. The system uses color-coded beads known as microspheres that react with test samples. Lasers are used to excite the internal dyes marking the sample while a high-speed digital signal processor identifies each individual microsphere and quantifies the results.

While many companies specialize in either DNA or protein analysis, Luminex is able to offer the versatility of assaying a wide range of biomolecules and reactions on one platform. The system offers high throughput and speed; because each microsphere serves an individual test a large numbers of bioassays can be performed and analyzed simultaneously.

Luminex has been marketing the current generation of this xMAP technology since 1999. The company generates recurring revenues through the sales of microspheres.

“We’re anxious to explore ways to adapt Luminex technology to our business,” said Dr. Neal Apple, VP of the Tyson Food Safety and Laboratory Services Network. “We believe it will give us the flexibility to gather more testing data faster and develop and validate rapid testing options not currently available commercially. We see a tremendous benefit to our customers, company and the food industry by applying this next generation technology to positively impact the effectiveness of our routine laboratory testing. This collaboration represents a big step forward for our labs and lines up with our focus on continuous improvement of our ISO (International Organization for Standardization) Quality System.”